Excel PCD CV (17 MM Dripline) w/ Check Valve

DIG’s Excel™ PCD CV Pressure compensating, Dual Outlet Dripline with Check Valve for subsurface irrigation is a reliable, durable and precise pressure compensating dripline used for narrow or dense plantings. The dripline’s cylindrical drip emitters have built-in check valves to prevent siphoning when water pressure drops below 2.5 PSI. This feature protects the inline emitters from sediment, soil particles and debris entering the dripline. Each cylindrical drip emitter’s floating diaphragm regulates and maintains a consistent flow rate at variable inlet pressures ranging from 12 to 50 PSI in a wide range of demanding conditions. Excel PCD CV Dripline includes a colored stripe for each flow rate, and unlike other driplines with only a single outlet, it has two outlets per emitter. If one outlet becomes blocked, a second outlet on the opposing side of the dripline provides redundancy to the dripline performance. Excel PCD CV Dripline is made of premium low-density polyethylene resins with UV protection and large, tough cylindrical drip emitters, offering a combination of outstanding environmental stress-cracking resistance and burst strength with anti-siphoning capability for subsurface irrigation applications.

Features

- Can be installed above or below grade

- Inline emitter check valves prevent drainage from the dripline when water pressure drops below 2.5 PSI, protecting the emitters against the siphoning of small sediment and soil particles into the drip emitter

- Two outlets per emitter; if one outlet becomes blocked, a second outlet on the opposing side of the dripline provides redundancy to the dripline performance

- Available in two flow rates, a wide range of emitters spacing and a wide range of drip tubing lengths to provide maximum design flexibility in a variety of applications

- Available with double stripes colored codes, representing the drip line flow rates

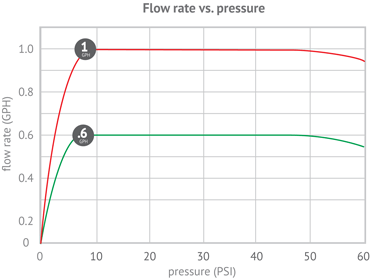

- Pressure compensating feature provides flow uniformity regardless of operating pressure and variation along the line

- Drip emitter and diaphragm are self-contained units molded to the interior wall of the tubing

- Flow path design supports superior clogging resistance

- Turbulent flow through large labyrinth water passages leads water into the flow control chamber where a sensitive floating silicon diaphragm regulates and maintains a constant flow rate at variable inlet pressures. The self-flushing silicon diaphragm allows pressure to build up within the chamber and flush any debris not captured by the inlet filter.

- Dripline includes one inlet and two outlets per each emitter

- Intake inlet has a number of raised grooves that act as a secondary filter. The filter intake area is continuously flushed by water flow throughout the operation of the system, preventing particles from entering the labyrinth and giving the drip emitter its resistance to clogging.

- Check valve and dual, oppositely oriented directional outlets act as a physical barrier to root and debris intrusion

- Resistant to chemicals and fertilizers commonly used in landscaping

- Protected against UV degradation

- Flexible tubing for easy installation

- Dripline is printed with the flow rate and size for easy identification

- Use with DIG’s 17 mm barb fittings, .670″ OD compression fittings and universal Nut Lock™ fittings

How to Specify

| MODEL | DESCRIPTION |

|---|---|

| 500' PC Dripline with CV | |

| A1-524P-CV | 24" spacing, 1 gPh, .670 od |

| A5-512P-CV | 12" spacing, .6 gPh, .670 od |

| A5-518P-CV | 18" spacing, .6 gPh, .670 od |

| A5-524P-CV | 24" spacing, .6 gPh, .670 od |

| A1-512P-CV | 12" spacing, 1 gPh, .670 od |

| A1-518P-CV | 18" spacing, 1 gPh, .670 od |

| 1000' PC Dripline with CV | |

| A5-12P-CV | 12" Spacing, .6 Gph, .670 Od |

| A5-18P-CV | 18" Spacing, .6 Gph, .670 Od |

| A1-12P-CV | 12" spacing, 1 gph, .670 od |

| A1-18P-CV | 18" spacing, 1 gph, .670 od |

| A1-24P-CV | 24" spacing, 1 gph, .670 od |

| 250' PC Dripline with CV | |

| A5-212P-CV | 12" spacing, .6 gph, .670 od |

| A5-218P-CV | 18" spacing, .6 gph, .670 od |

| A5-224P-CV | 24" spacing, .6 gph, .670 od |

| A1-212P-CV | 12" spacing, 1 gph, .670 od |

| A1-218P-CV | 18" spacing, 1 gph, .670 od |

| A1-224P-CV | 24" spacing, 1 gph, .670 od |

| 100' PC Dripline with CV | |

| A5-112P-CV | 12" spacing, .6 gph, .670 od |

| A5-118P-CV | 18" spacing, .6 gph, .670 od |

| A1-112P-CV | 12" spacing, 1 gph, .670 od |

| A1-118P-CV | 18" spacing, 1 gph, .670 od |

Specifications

- Flow rates:

- .6 GPH (2.3 L/H) drip emitter color code - orange

- Drip line double stripe code - beige

- 1 GPH (3.8 L/H) drip emitter color code - gray

- Drip line double stripe code - gray

- Operating pressure: 12-50 PSI (.8-3.5 BAR)

- Check valve sealing pressure: 2.5 PSI (.17 BAR)

- Check valve opening pressure: 4.3 PSI (.3 BAR)

- Materials: Dow FINGERPRINT™ DFDA-7510 NT linear low-density polyethylene resin with a minimum of 2% carbon black

- Dripline color: brown

- Size: 1/2" (.570" ID x .670" OD)(14.5 mm ID x 17 mm OD)

- Spacing: 12", 18" or 24" (30.5 cm, 45.7 cm and 61 cm)

- Available in 100', 250', 500' and 1000' coils (30 m, 75 m,150 m and 300 m)

- Minimum bending radius: 1' (.3 m)

- Filter requirement: minimum of 150 mesh

Maximum single lateral length Flow rate .6 GPH (2.3 L/H) DOUBLE STRIPE COLOR, BEIGE

| Dripper Spacing | 15 PSI (1.0 BAR) | 25 PSI (1.7 BAR) | 35 PSI (2.4 BAR) | 45 PSI (3.2 BAR) |

|---|---|---|---|---|

| 12" (30 m) | 215' (65 m) | 304' (92 m) | 343' (104 m) | 442' (134 m) |

| 18" (45 m) | 244' (74 m) | 406' (123 m) | 459' (139 m) | 548' (166 m) |

| 24" (60 m) | 370' (112 m) | 482' (146 m) | 617' (187 m) | 772' (234 m) |

Maximum single lateral length Flow rate 1.0 GPH (3.8 L/H) DOUBLE STRIPE COLOR, GRAY

| Dripper Spacing | 15 PSI (1.0 BAR) | 25 PSI (1.7 BAR) | 35 PSI (2.4 BAR) | 45 PSI (3.2 BAR) |

|---|---|---|---|---|

| 12" (30 m) | 145' (44 m) | 185' (56 m) | 248' (75 m) | 287' (87 m) |

| 18" (45 m) | 221' (67 m) | 294' (89 m) | 347' (105 m) | 413' (125 m) |

| 24" (60 m) | 294' (89 m) | 403' (122 m) | 479' (145 m) | 512' (155 m) |

Flow rate per 100 feet (30 M) (Flow rate 0.6 GPH)

| Dripper Spacing | Flow (GPM) | Flow (L/M) | Flow (GPH) | Flow (L/H) |

|---|---|---|---|---|

| 12" (30 cm) | 1.00 | 3.8 | 60 | 227 |

| 18" (45 cm) | 0.67 | 2.5 | 40 | 151 |

| 24" (60 cm) | 0.50 | 1.9 | 30 | 114 |

Flow rate per 100 feet (30 M) (Flow rate 1.0 GPH)

| Dripper Spacing | Flow (GPM) | Flow (L/M) | Flow (GPH) | Flow (L/H) |

|---|---|---|---|---|

| 12" (30 cm) | 1.67 | 6.3 | 100 | 379 |

| 18" (45 cm) | 1.11 | 4.2 | 66.7 | 252 |

| 24" (60 cm) | 0.83 | 3.2 | 50 | 189 |

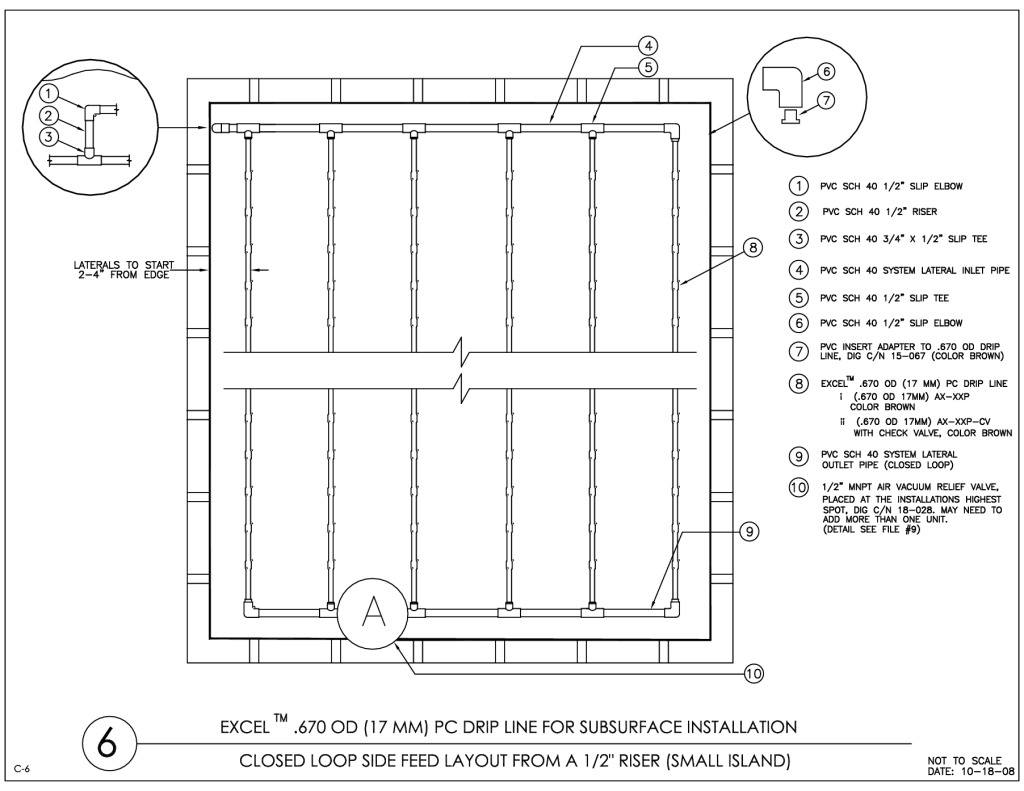

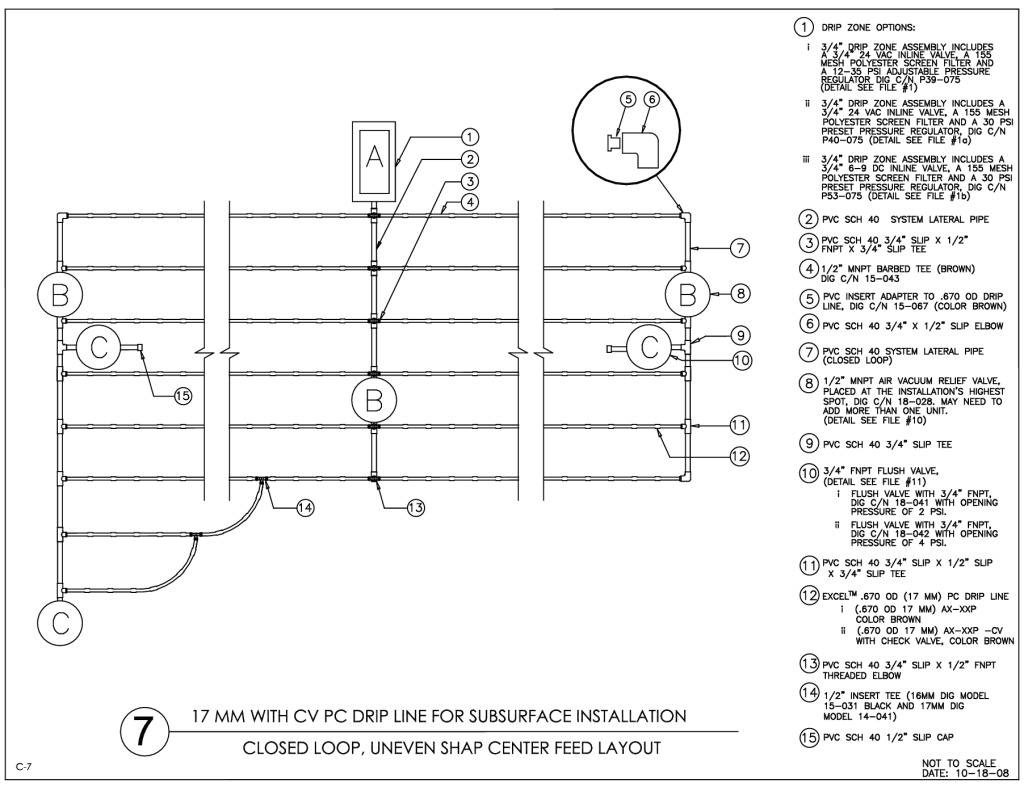

CAD Files

-

17 mm Excel™ PC-CV Pressure Compensating Drip Line With Check Valve

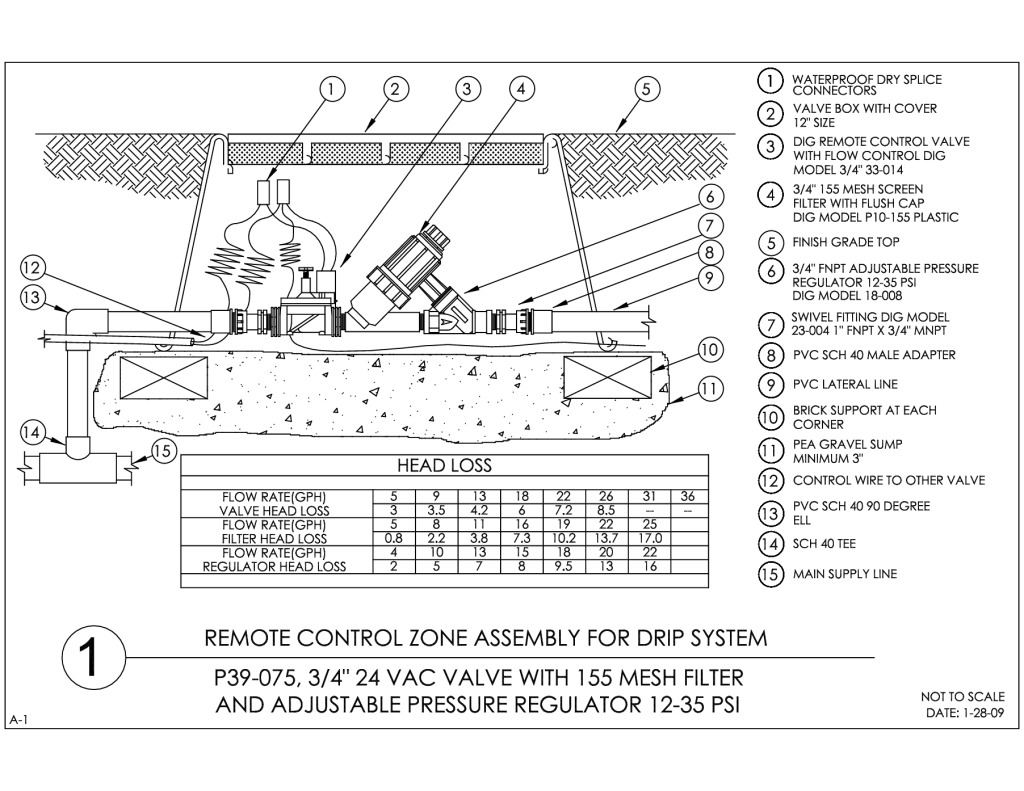

- 1 Remote Control Zone Assembly for Drip System P39-075

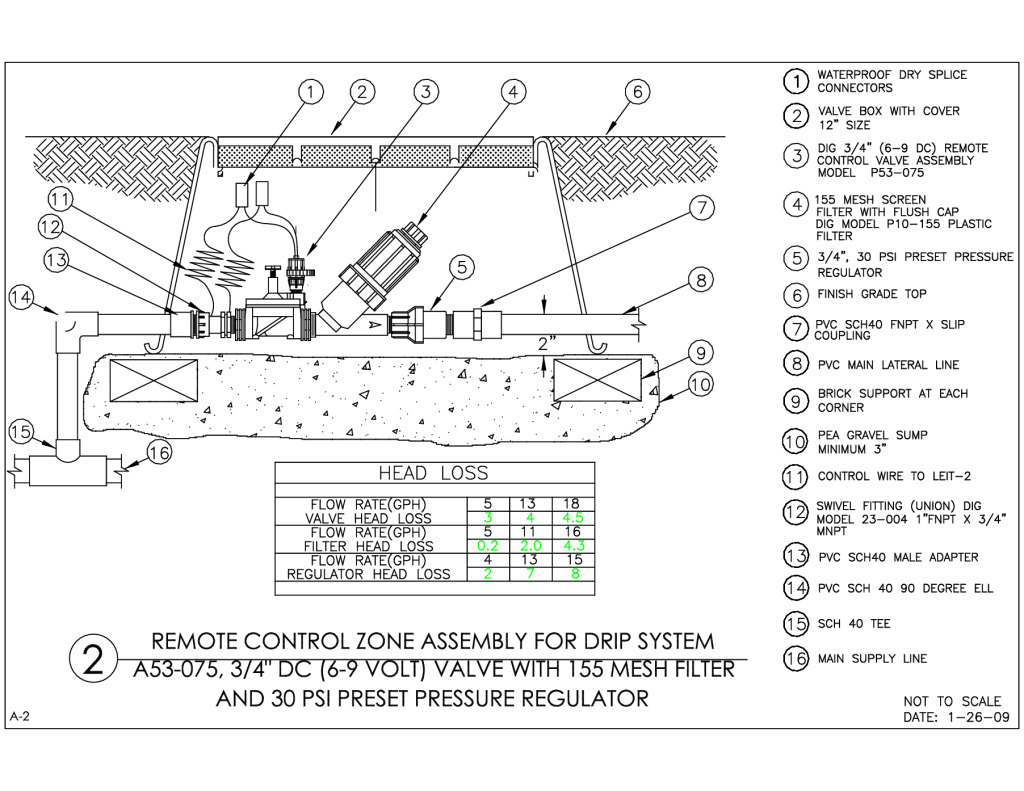

- 2 Remote Control Zone Assembly for Drip System A53-075

- 3 Excel™ drip line for subsurface installation, side view

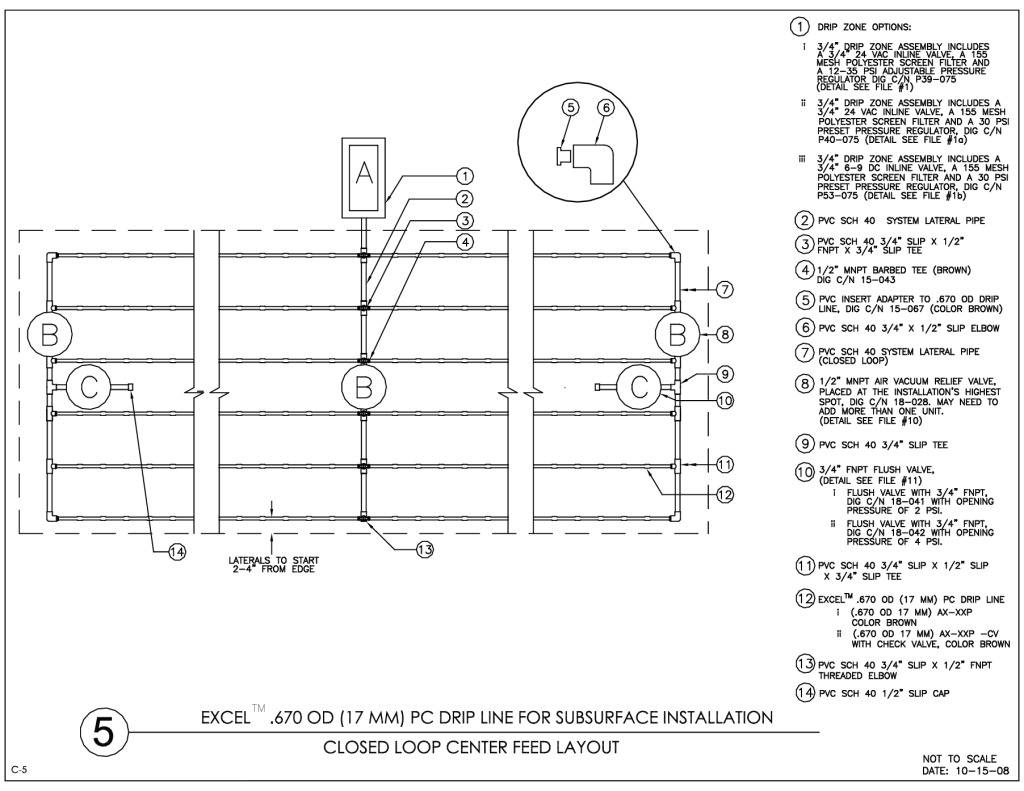

- 4 Excel™ drip line for subsurface installation, closed loop center feed layout

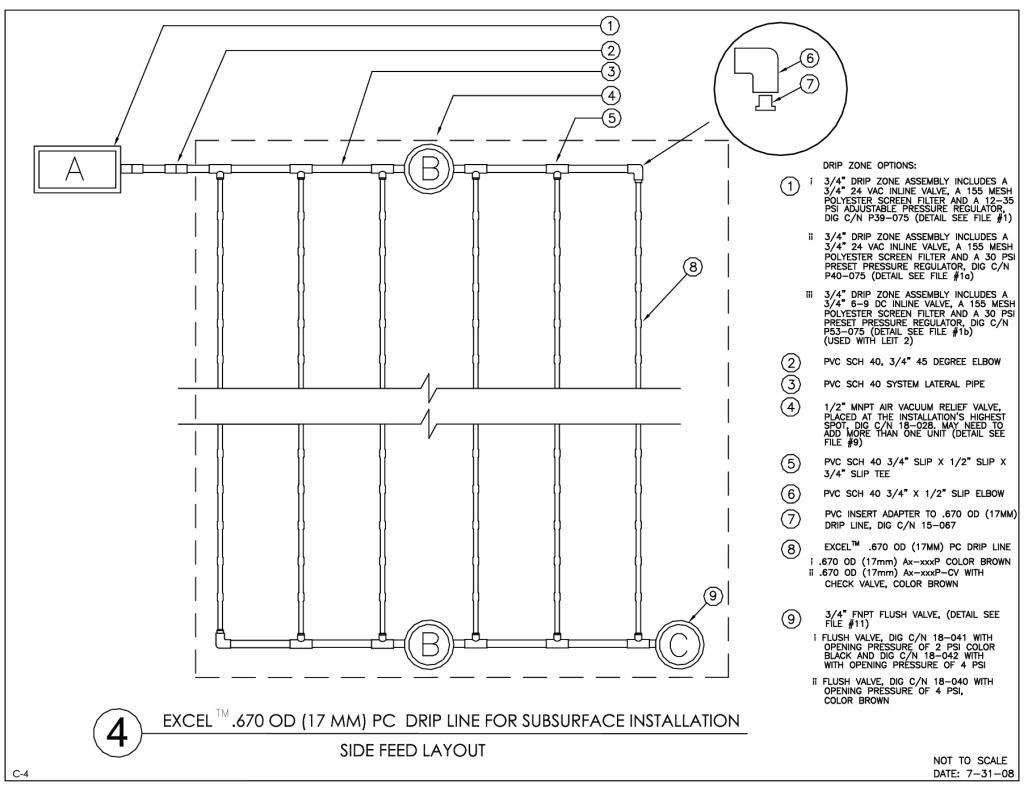

- 5 Excel™ drip line for subsurface installation, side feed layout from a 1/2" riser

- 6 Excel™ drip line for subsurface installation, closed loop, uneven shape center feed layout

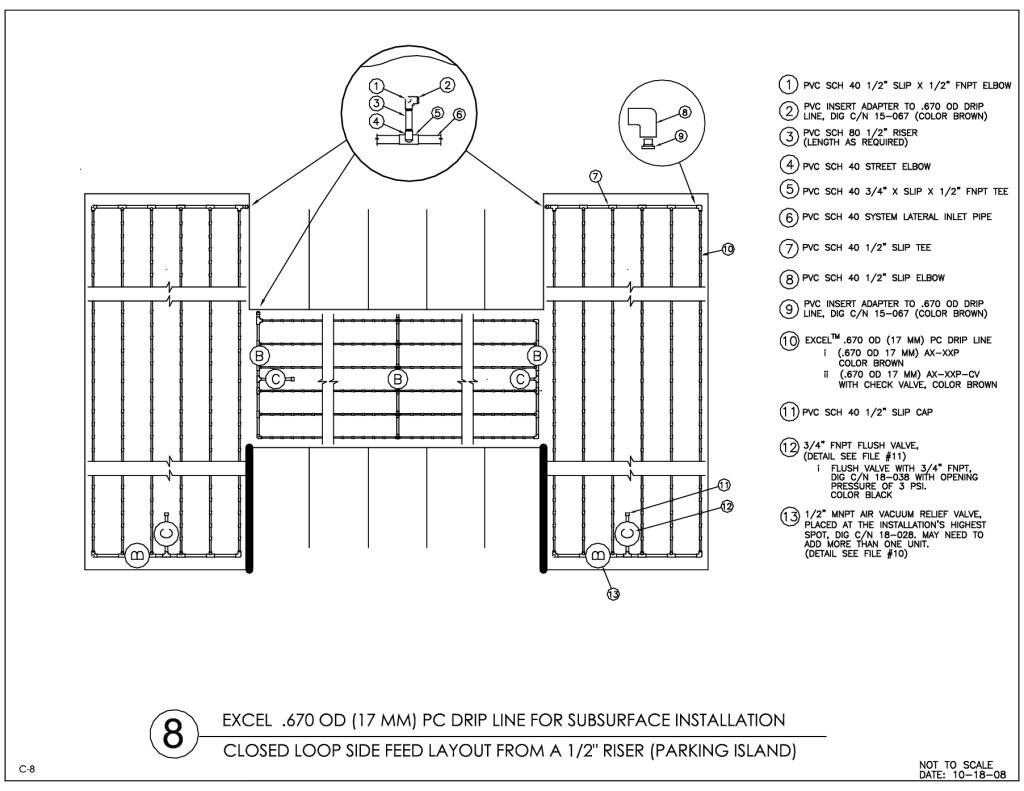

- 7 Excel™ line for subsurface installation, closed loop side feed layout from 1/2" riser (parking island)

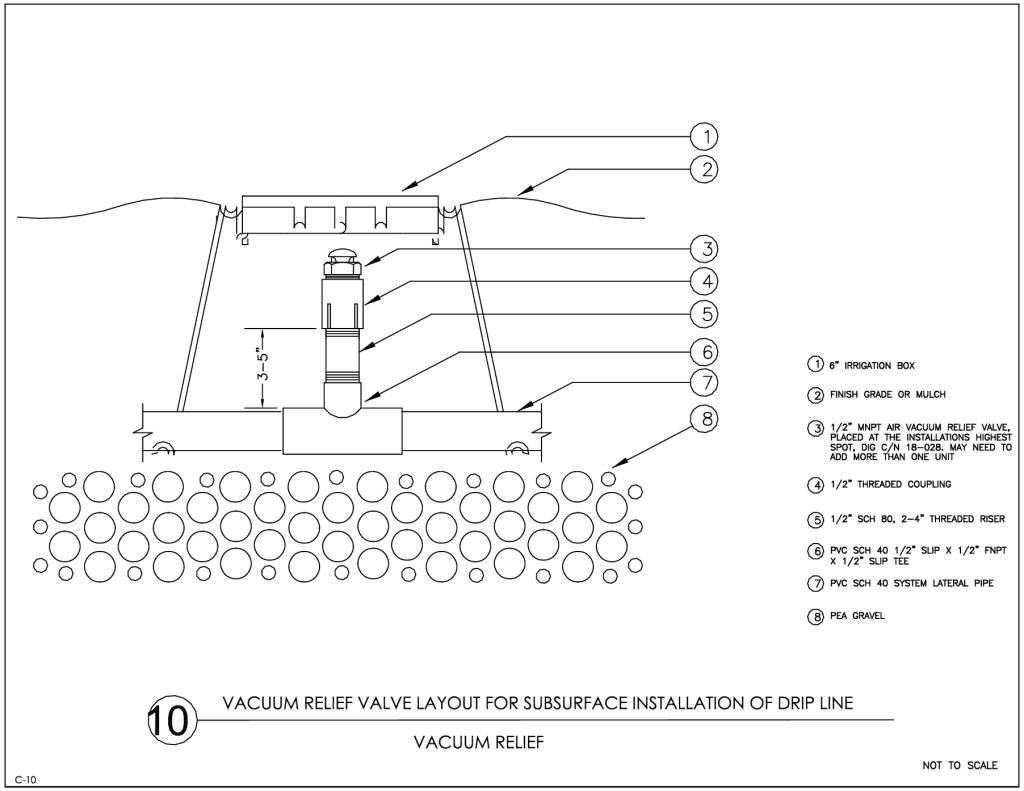

- 8 Vacuum relief valve layout for subsurface installation of drip line

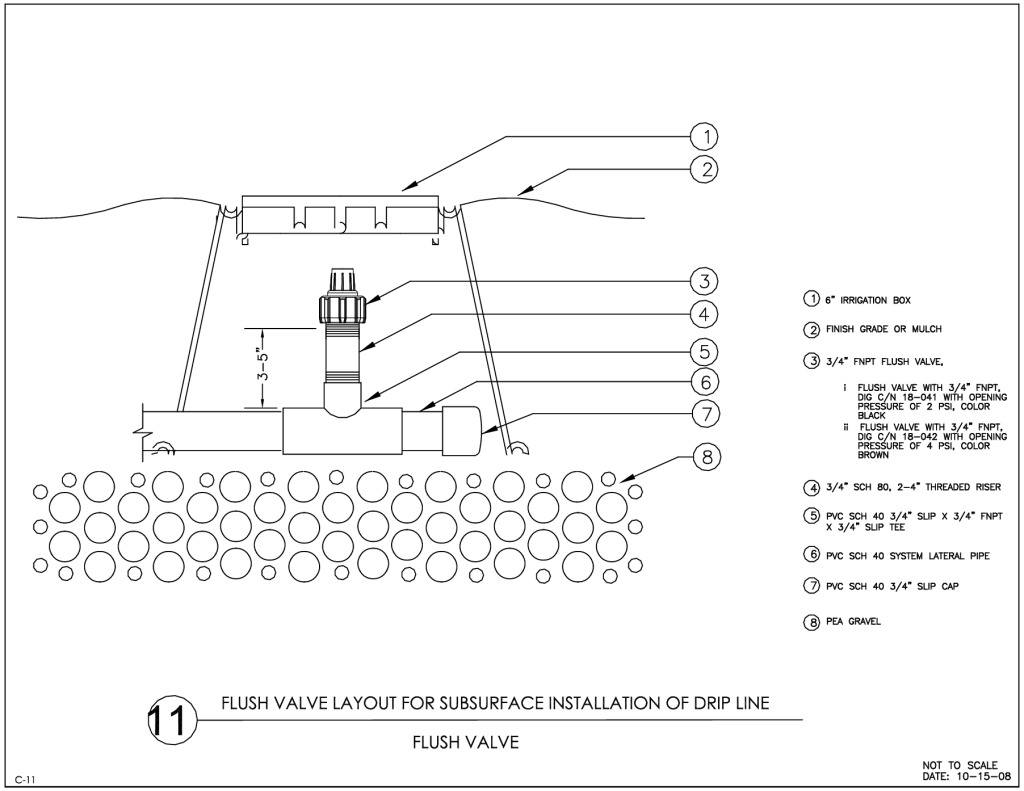

- 9 Flush valve layout for subsurface installation of drip line

English

English  Spanish

Spanish