Fan Micro Sprayers

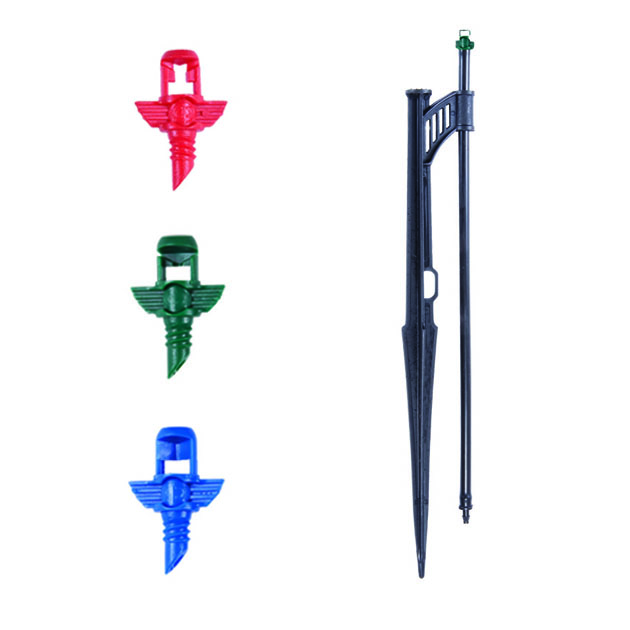

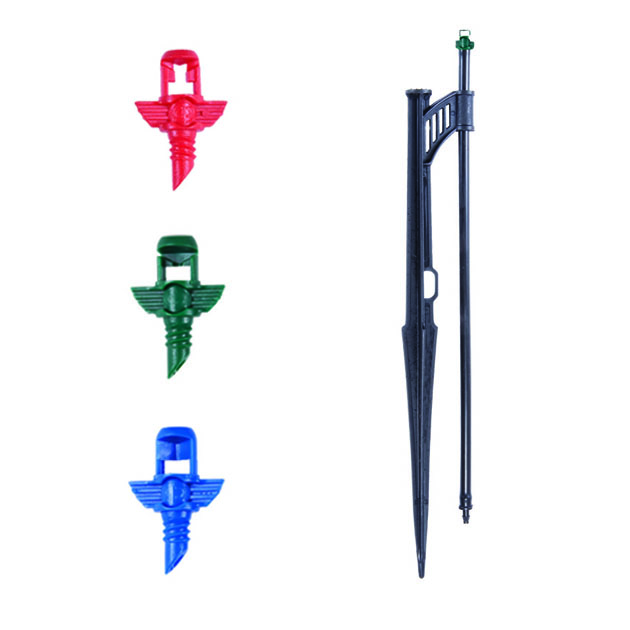

DIG’s easy-to-install Fan Micro Sprayers, available in single unit packs and fully assembled with a 13” stake, 12” PE riser and 1/4″ barb, offer 360° (model 107-1B), 180° (model 108-1B) and 90° (model 109-1B) diameter full-circle spray patterns with a flow of 8.1 to 40.3 GPH at 25 PSI. They have reduced susceptibility to clogging due to larger sized orifices and can be installed in a wide range of applications. Used for residential gardens, flowerbeds, groundcovers, shrubs and trees, the micro sprayer are ideal for areas where low flow overhead irrigation is desired or for areas where drip emitters or conventional sprinkler systems are not practical.

Features

- Easy to install using a complete assembly unit on 13″ spike with 12” PE riser and barb

- Available in 90°, 180° and 360° diameter for individual plants or closely spaced plantings

- The single part micro sprayer has a quick thread base with wide wing edges for easy removal and cleaning

- Three color-coded bases for easy identification

- Efficient and reliable method to apply water

- Low flow rate with fine fan spray, preventing run-off in heavy soil

- Constructed of UV-resistant, durable plastic material to withstand the most adverse conditions

How to Order

| MODEL | DESCRIPTION | COLOR |

|---|---|---|

| Fan Spray Jets on Spike | ||

| 109-1B | 90° Fan Spray Jet Complete Assembly (Pack of 1) | Blue |

| 108-1B | 180° Fan Spray Jet Complete Assembly (Pack of 1) | Green |

| 107-1B | 360° Fan Spray Jet Complete Assembly (Pack of 1) | Red |

Specifications

- Operating pressure range: 15 to 30 PSI

- Recommended operating pressure: 25 PSI (use with model D46 25-PSI pressure regulator)

- Flow rate @ 25 PSI:

- Model 107-1B with 360°, color code red: 40.3 GPH

- Model 108-1B with 180°, color code green: 21.3 GPH

- Model 109-1B with 90°, color code blue: 8.1 GPH

- Recommended spacing: 3' to 8' apart

- Filter requirement: minimum of 80 mesh

- Material:

- Riser: PE

- Stake: polypropylene

- Fan Sprayer: high-impact plastic

- Barb: high-impact plastic

Flow rate, radius and diameter

| Pressure | Spray | Flow rate | Radius |

|---|---|---|---|

| PSI | head | GPH | 90° |

| 15 | Blue .030" | 6.2 | 3.3' |

| 20 | Blue .030" | 7.3 | 3.5' |

| 25 | Blue .030" | 8.1 | 3.7' |

| 30 | Blue .030" | 8.9 | 3.9' |

| PSI | head | GPH | 180° |

| 15 | Green .060" | 16.4 | 5.1' |

| 20 | Green .060" | 19.0 | 5.5' |

| 25 | Green .060" | 21.3 | 5.8' |

| 30 | Green .060" | 23.3 | 6.1' |

| Pressure | Spray | Flow rate | Diameter |

| PSI | head | GPH | 360° |

| 15 | Red .080" | 31.5 | 9.9' |

| 20 | Red .080" | 36.2 | 10.3' |

| 25 | Red .080" | 40.3 | 10.8' |

| 30 | Red .080" | 44.0 | 11.2' |

Maximum number of fan sprayer jets on 1/2" drip tubing with .600 ID @ 25 PSI

| 180° micro sprayer spacing | 4' | 5' | 6' | 7' | 8' |

|---|---|---|---|---|---|

| Flow rate @ 25 PSI | 21.3 | 21.3 | 21.3 | 21.3 | 21.3 |

| Maximum length | 52' | 60' | 66' | 77' | 80' |

| Flow rate in GPM | 4.62 | 4.26 | 3.91 | 3.91 | 3.55 |

| Flow rate in GPH | 276.9 | 255.6 | 234.3 | 234.3 | 213 |

| # of fan sprayer jets | 13 | 12 | 11 | 11 | 10 |

| Head loss in PSI | 5.1 | 5.1 | 4.8 | 5.6 | 4.9 |

| Velocity (f/s) | 5.25 | 4.84 | 4.44 | 4.44 | 4.03 |

| 24" micro tubing head loss in PSI | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Total head loss at the spray head | 5.5 | 5.5 | 5.2 | 6.0 | 5.3 |

| 360° micro sprayer spacing | 4' | 5' | 6' | 7' | 8' |

|---|---|---|---|---|---|

| Flow rate @ 25 PSI | 40.3 | 40.3 | 40.3 | 40.3 | 40.3 |

| Maximum length | 32' | 40' | 42' | 49' | 56' |

| Flow rate in GPM | 5.37 | 5.37 | 4.70 | 4.70 | 4.70 |

| Flow rate in GPH | 322.4 | 322.4 | 282.1 | 282.1 | 282.1 |

| # of mini sprinklers | 8 | 8 | 7 | 7 | 7 |

| Head loss in PSI | 4.2 | 5.2 | 4.2 | 5.0 | 5.7 |

| Velocity (f/s) | 6.1 | 6.1 | 5.34 | 5.34 | 5.34 |

| 24" micro tubing head loss in PSI | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 |

| Total head loss at the spray head | 5.5 | 6.5 | 5.5 | 6.3 | 7.0 |

About

The Fan Micro Sprayers are available with full-, half- and quarter-circle patterns and with a flow rate of 8.1 to 40.3 GPH at 25 PSI. Using a PE riser extension, the height of the sprayer can be adjusted to fit taller plants and higher vegetation growth. The higher the position of the micro sprayers above the ground, the larger the wetted area. These fan micro sprayers are available in a complete assembly with a 13” stake, 12” PE riser and 1/4” barb for added flexibility in the product installation. Use the micro sprayers when overhead watering is suggested on any type of planting, including vegetation that requires moisture, groundcovers, flowerbeds or individual trees along the poly tubing. The ideal spacing is three to five feet between the adjustable spray heads or one per tree to a maximum distance of 32′ to 80′ in length, depending on flow rate, using 1/2” drip tubing as the main lateral.

The micro sprayers are an efficient and reliable method to apply water. To cover densely planted areas, place the micro sprayers close together in rectangular or triangular spacing for good overlapping irrigation and better uniformity. Do not use the micro sprayers in windy areas as their small size droplets can be easily dispersed in the air, even under low to moderate wind conditions, adversely affecting uniformity. The main advantage of low flow micro irrigation is that a relatively large number of micro sprayers can operate simultaneously.

Installation

The micro irrigation systems consist of a system “head” assembly and distribution laterals. The system head assembly consists of a backflow device, filter, fertilizer injector (optional) and pressure regulator. Generally, the head assembly parts can be found in any store that carries drip irrigation components. The fertilizer applicator and AC or DC controllers are optional equipment but highly desirable because they can add flexibility to the system. The distribution laterals consist of main line pipes, usually made of PVC, the sub lateral pipes, made of polyethylene (PE), fittings and accessories. The system can be automated electronically by adding an AC controller connected to an AC solenoid valve, a hose end timer or a battery operated controller.

Installation suggestions

Basic installation recommendations for this product include first reviewing the area and then making a drawing of the garden or site with your preferred layout.

If automation is required, use one of DIG’s hose end timers or battery operated controllers. The ideal controller should have flexible scheduling and two to four start times per day for added flexibility.

Start the installation from a PVC pipe or to pipe thread

- If the system installation is started from a PVC pipe, first shut off the main water supply.

- If an automated system is preferred, we recommend installing a 3/4” ball valve or gate valve before the battery operated controller or AC valve, if used. This ball valve can be very useful as an emergency backup to turn the system off. This type of arrangement is used by professional installers.

- Turn the water supply on to flush the line and then shut the water supply off using the new ball or gate valve.

- Install an AC valve or battery operated controller, wrapping TEFLON tape on all the male thread fittings used.

- Turn the water supply on again to pressurize the system. The unit will open momentarily and then will shut off.

- Test the valve or the battery operated controller and make sure that it is working correctly. If using a battery operated controller, program it.

- After the AC valve or battery operated controller, add a 3/4” screen filter with 155-mesh (model D55). The screen filter is used to protect the drip system. Next, add a preset 25 PSI pressure regulator (model D46P) or adjustable pressure regulator (model PRV075). The pressure regulator is used to lower the pressure to the suggested operating pressure for a drip system. Follow with a 3/4” swivel adapter (model 50001) to the drip tubing or 3/4” PVC thread x slip adapter to the PVC line.

Start the installation from a faucet or hose thread

- If an automated system is preferred, install a hose end timer.

- Test the timer and make sure that it is working correctly, then program it. To the timer, add a backflow device (model D45), then a 25 PSI pressure regulator (model D46) and then a 3/4″ swivel adapter with screen (model C34). If water quality is a concern, we highly recommend using a fine mesh 3/4″ filter with 155-mesh (model D57A).

Product installation

- Using the drip irrigation tubing as the main lateral or sub lateral, lay out the drip tubing per your layout drawing. Secure the drip tubing to the ground using stakes (model R60). Use the stakes to secure the drip tubing to the ground in key areas and add more stakes as you unroll the drip tubing. Add stakes every 20′-30’ and at the end of each section, or as needed. An extra 1% of drip irrigation tubing length should be added to each lateral to compensate for contraction at low temperature.

- Throughout the installation and per your drawing layout, add, if needed, 1/2″ fittings, such as tees (model C35) and elbows (model C36), leaving the end of the drip tubing open. To install the 1/2″ compression drip fittings, cut the drip tubing with a hand pruner, being careful to keep dirt from entering the line. Hold the fitting in one hand and the drip tubing in the other and force the drip tubing into the compression fitting by wiggling it from side to side.

- The micro sprayers are installed along the drip tubing at varying or at specific intervals. The distribution uniformity of water from the micro sprayers along the line depends on the incoming pressure, number of micro sprayers used per lateral and the length of the laterals. Special care should be taken to ensure high uniformity of water along the laterals by not exceeding the product recommendations (see chart).

- To install the complete assembly micro sprayer, punch a hole into the top of the drip tubing using the small punch (model D44) or the gun punch (model 16-035), snap the 1/4” barb at the end of the 12” PE tubing assembly into the drip tubing and insert the stake to the ground, keeping the micro sprayer head at a minimum of 8” above ground for best coverage.

- Turn the water on and flush the line.

- Close the end of the drip tubing using the hose end (model Q58) or figure “8” (model F68B).

- Pressure-test the system to identify leaks in the drip tubing laterals, fittings and micro tubing, and then program the hose end timer or battery operated controller.