Drip Irrigation Supply Tubing & Fittings

by Stuart Spaulding —

CLIA Certified Landscape Irrigation Auditor Training & Communications Manager at DIG Corp.

The polyethylene supply tubing produced today for drip irrigation systems is a far superior product compared to the tubing that was manufactured in years past. Significant advances in extruding technology and refinements in the processing and blending of raw materials have led to the production of polyethylene tubing that has a longer lifespan, a higher resistance to degradation from UV rays, and greater protection from thermal degradation. In short, todays drip irrigation poly tubing will stay flexible and functional for decades even if it is exposed to direct sunlight in challenging environments.

“Half Inch” Poly Tubing is not Half Inch

But unfortunately, there is one aspect of drip irrigation poly tubing that remains unchanged, and that is the fact that the tubing is still “nominally” sized. Unlike PVC pipe, there is no industry or global standard for the outside diameter (O.D.) of poly tubing. Currently, there are three different sizes of so-called ½ inch poly tubing, they all have slightly different inside (I.D.) and outside diameters, and none of them are ½ inch! It may help to make the comparison to the way lumber is specified…take a common two by four for example. They are sold in the lumber yard in a variety of lengths, under the two by four name. But the actual height and width are not 2” by 4”. The typical dimensions are closer to 1.5” by 3-3/8”. But they have always been called two by fours- not technically accurate, but again this is a good example of a nominally sized commodity.

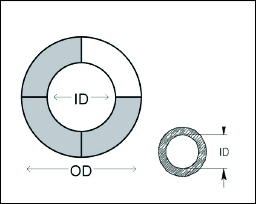

Inside and Outside Diameter & Compression Fittings

The three main sizes of so-called half-inch poly tubing are:

1) .520” ID X .620” OD

(smallest of the three, becoming obsolete, uses compression fittings with green inserts)

2) .600” ID X .700” OD

(the most common size in retail stores, uses black compression fittings)

3) .620” ID X .710” OD

(sometimes called 5/8”, may have a blue stripe, takes compression fittings with a blue insert)

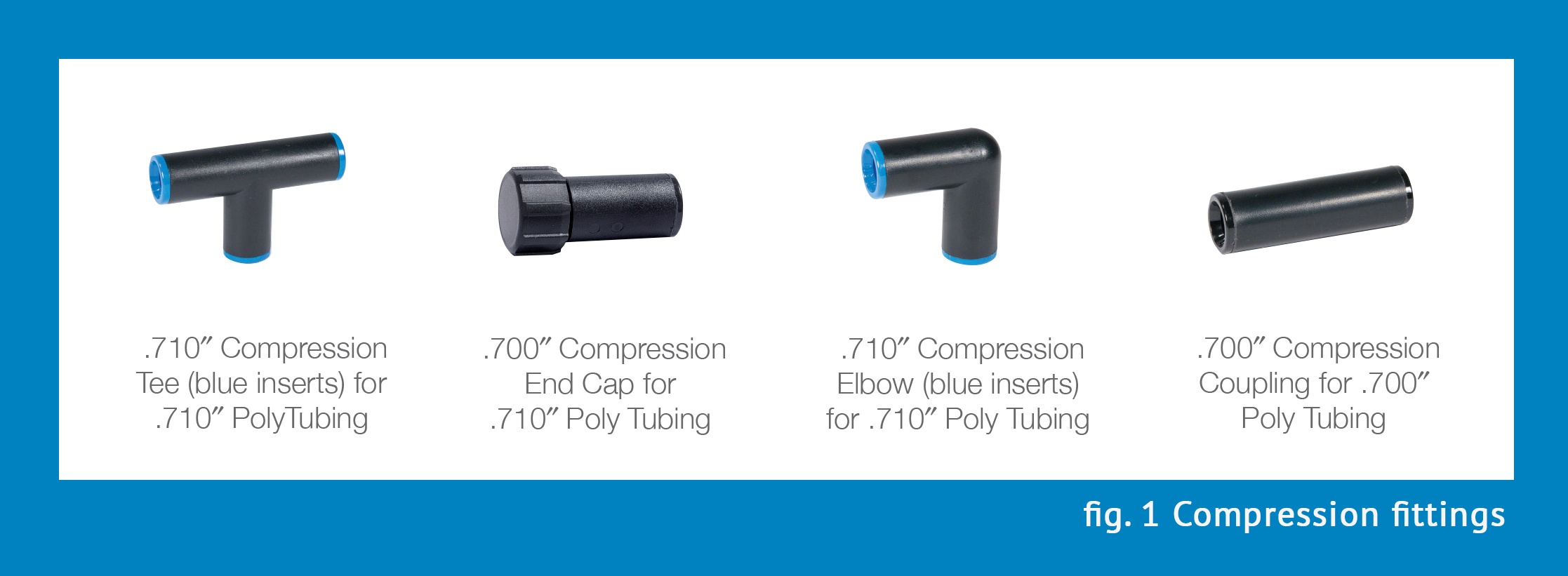

The outside diameter is critical when it comes to selecting compression fittings, because these fittings seal against the outside of the tubing. The tubing is connected to the fitting by forcing the end of the tubing into the fitting while moving it from side to side, gradually, until the end is about ¾” inside the fitting. The fitting has an interior lip that allows the tubing to go in but not out. These fittings are designed for one time use and are not easily removed from the tubing after installation. Compression fittings are available in a variety of configurations including coupler, elbow, tee, end cap, hose adapter and more. (fig. 1)

New Installations

It is not so difficult to determine the outside diameter of the tubing in the store or online. The outside diameter is usually printed on the outside of the tubing itself, or on the products’ packaging or label. And since the compression fittings are color coded, it’s easy to select the proper size. Use the all black fittings for .700” OD tubing, green for the .620” and blue for the .710” OD poly tubing. The store should stock the appropriate fittings for the tubing they sell. Please be aware that most stores stock more than one size of poly tubing.

Existing Installations

It is not uncommon for identification problems to occur when installers are dealing with existing systems. This is because over time, the lettering on the outside of the tubing can fade away, and there may be no color- coded fittings available to indicate the tubing size. The less common .620” OD poly tubing is noticeably smaller than the larger sizes, but even a trained experienced person cannot easily notice the difference between .700” & .710” tubing. One way to judge the size of the tubing is by how it fits into a fitting. The tubing should require a fair amount of effort to force into the fitting, but not too much. If it slips in easily then the fitting is probably too large for the tubing. But if this is too problematic, fear not, there is a solution, universal fittings are now available that will fit all three sizes of ½” poly tubing.

Universal Poly Tubing Fittings

The universal type of tubing fittings presently available in a variety of designs that typically utilize a threaded nut to connect the fittings to all three of the sizes of ½” poly tubing. They cost a bit more than basic compression fittings, but they are very useful especially when the installer is not certain of the tubing size. These fittings can also be removed and re-used if necessary. The variety of configurations is more limited however, and are usually only available in Tee, elbow or coupler.

A Universal Nut Lock™ fitting will fit all three sizes of ½” poly tubing

Hydraulic Specifications/Limitations

FLOW RATE: Since the poly tubing is the main supply line for majority of non-commercial drip irrigation systems, it is very important to know how much water it can deliver without creating hydraulic problems like excessive water velocity or pressure. Remember that drip systems apply water at lower pressure and at lower flow rates (gallons per hour-GPH) than sprinkler systems (gallons per minute-GPM). Of course, the larger the inside diameter, the more water the tubing can deliver. The maximum flow rate for .700” OD and .710” OD poly tubing is approximately 220 gallons per hour. This means that the total of the flow rates for all the emission devices connected to the line should not exceed 220 GPH.

DISTANCE LIMITATIONS: The maximum distance limit for ½” poly tubing depends on the flow rate but a safe number to use is not to exceed 350’ for any single run length.

OPERATING PRESSURE: The poly tubing should be used on drip systems only and operated in the range of 20 to 40 psi. This usually means that a pressure regulator should be installed to lower the dynamic (operating)pressure. The tubing is typically rated to handle a maximum of 60 PSI, but it never should be installed upstream of a remote-control valve where it will be subject to continuous pressure.

Larger Sizes of Poly Tubing

The ½ inch sizes of drip supply tubing are the most common sizes in use today, but there are also larger sizes produced and installed, although they are mainly used in commercial and agricultural installations.

.820” ID X .940” OD

Also known as ¾” poly tubing

maximum flow rate = 450 GPH

1.060” ID X 1.200” OD

Also known as 1” poly tubing

maximum flow rate = 700 GPH

The ¾” and 1” tubing can be run for a much longer distance that the ½” poly and are often used as a header or as a supply line to feed ½” poly tubing laterals. These larger sizes are typically used on commercial drip/low volume irrigation systems with higher total flow rates which connect to an automated irrigation valve.

There are two types of fittings that can be used with ¾” poly tubing. Specialized compression fittings are available in many configurations (similar to ½” compression fittings) which fit over the outside of the tubing. Also available for ¾” and 1” poly tubing are barbed insert fittings and adapters which are forced into the end of the tubing and are sometimes held in place with a hose clamp.

There are two types of fittings that can be used with ¾” poly tubing.

When selecting either of these fittings it is essential to identify the ID and/or OD of the tubing and verify that it is compatible with the fittings selected. Like the smaller ½” tubing, the larger diameter poly tubing will be easier to work with after it is uncoiled and laid out in direct sunlight for about 20 minutes. This will warm the tubing and make it more pliable and easier to force into fittings and reduce the tendency to re-coil during installation.

Closing Comments

We hope that the information contained in this article can help to inform the installer, do it yourselfer and designer to the facts about these products with the goal to ultimately reduce the headaches and problems that can occur due to lack of knowledge and/or installation experience. More information and details about poly tubing, fittings and other drip irrigation products are available in print and online, and many free resources are available at www.digcorp.com or www.irrigation.org. Thank you for reading and please keep an eye out for our next blog, which will attempt to clarify and inform you about another aspect of drip and low -volume irrigation systems. ∼